Rotating Machines

Petasense can be used to detect and predict most common failure modes in rotating machines. These include bearing wear, misalignment between the drive and the driven equipment, imbalance and looseness.

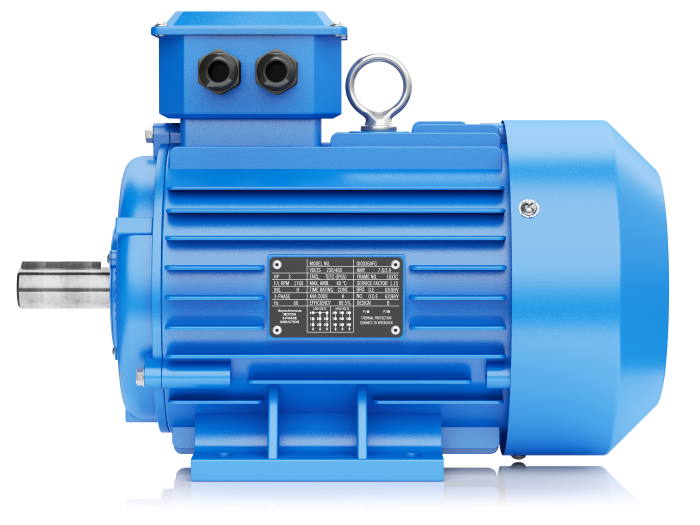

Motors

Motors are the primary movers in a manufacturing plant or a commercial facility . Petasense helps prevent unplanned downtime caused by most common failure modes of fixed and variable-speed motors.

- Uses

- – Detect misalignment, imbalance, looseness and bearing wear

- – Accurately detect mechanical defects in variable speed-driven equipment

-

– Detect electrical defects like cracked rotor bars and eccentricity

– Compute running speed

– Measure the operating load

– Measure & optimize energy utilization -

– Detect late-stage bearing issues

– Determine lube oil thickness and quality

- – Detect lubrication issues and very early-stage bearing wear

Pumps

Whether you’re moving petroleum, condensate or beer, pumps keep processes flowing in virtually every industrial environment. Petasense helps monitor and optimize a variety of pumps, including condensate pumps, API pumps and water feed pumps.

- Uses

-

– Detect misalignment, imbalance, looseness, bearing defects and cavitation

– Identify coupling and belt failure -

– Identify flow problems

– Detect impeller wear and seal failure

– Find BEP (best efficiency point) -

– Detect late-stage bearing issues

– Determine lube oil thickness and quality - – Detect early-stage bearing defects and lubrication issues

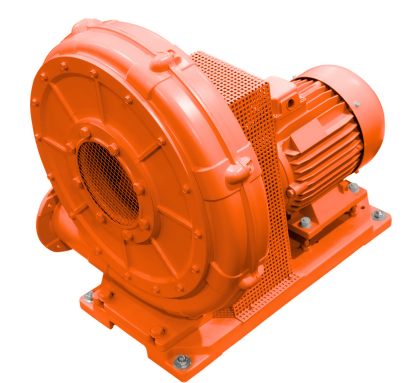

Fans

Fans, blowers and air handler units are commonly used in a wide variety of industrial sectors. Common applications include cooling towers, HVAC systems and exhaust systems. Petasense helps with the optimal operation of industrial fans.

- Uses

-

– Detect resonance and flow turbulence

– Detect belt problems -

– Detect Late stage bearing problems

– Determine lube oil thickness and quality - – Detect early-stage bearing defects and lubrication issues

Compressors

Compressors are used to bring gases from a lower pressure, at the intake, to a higher pressure, at the exhaust, by reducing the volume of the gas. Compressors are commonplace in HVAC systems, chemical production, oil & gas and power generation. Some of the most common designs are rotary screw compressors, reciprocating compressors and centrifugal compressors.

- Uses

- – Detect coupling misalignment, rotor unbalance, pulsation problems, crosshead looseness and bearing defects

- – Detect Seal Wear

- – Detect late-stage bearing issues

- – Detect lubrication issues, cracked blades and very early-stage bearing wear

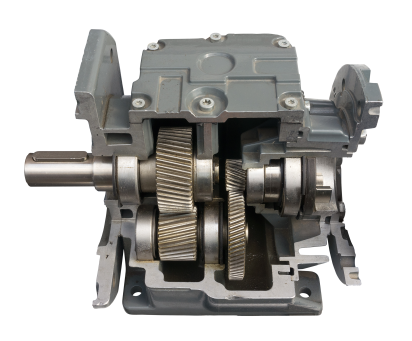

Gearboxes

Gearboxes are prevalent in industrial plants and are used to transmit power between shafts. They help change the rotating speed or direction of the shaft of the driven component.

- Defects

-

– Detect tooth wear or excessive tooth load

– Detect gear eccentricity and misalignment

– Detect bearing defects

– Identify broken or cracked teeth - – Detect late-stage bearing issues

- – Detect very early-stage bearing wear and lack of lubrication

Industrial IoT Sensors

Plug-and-play devices for predictive maintenance of rotating machines

Transmitter

Versatile, wireless sensor input device for measuring any industrial sensor parameter