How it Works

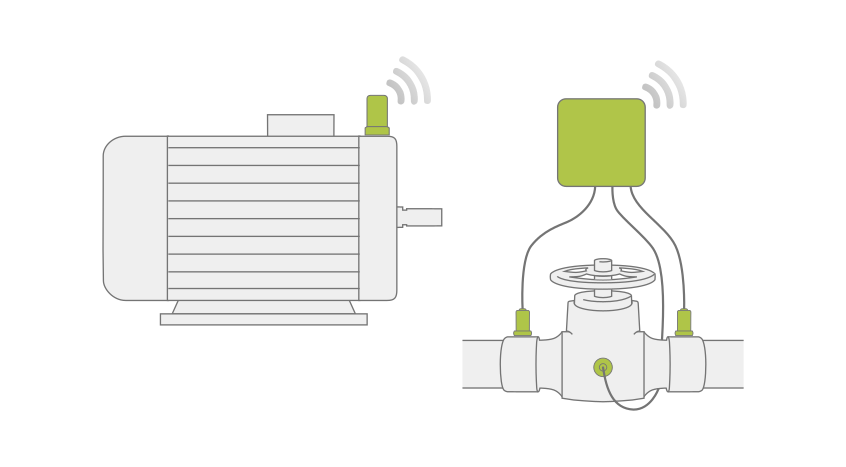

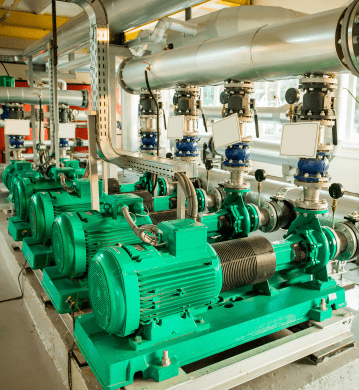

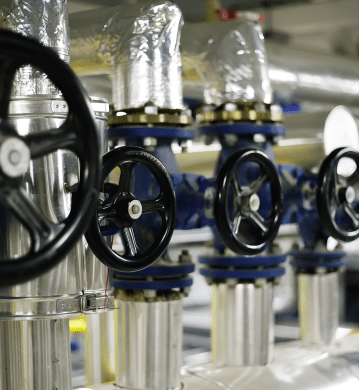

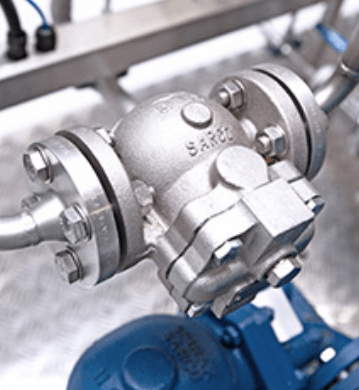

Wireless Sensors

Quickly deploy plug-and-play industrial IoT sensors for real-time condition monitoring—no complex wiring or IT integration needed.

AI-Powered Analytics

in the CloudYour machine data is securely transmitted to the cloud, where our machine learning algorithms detect anomalies, track failure modes, and predict asset health.

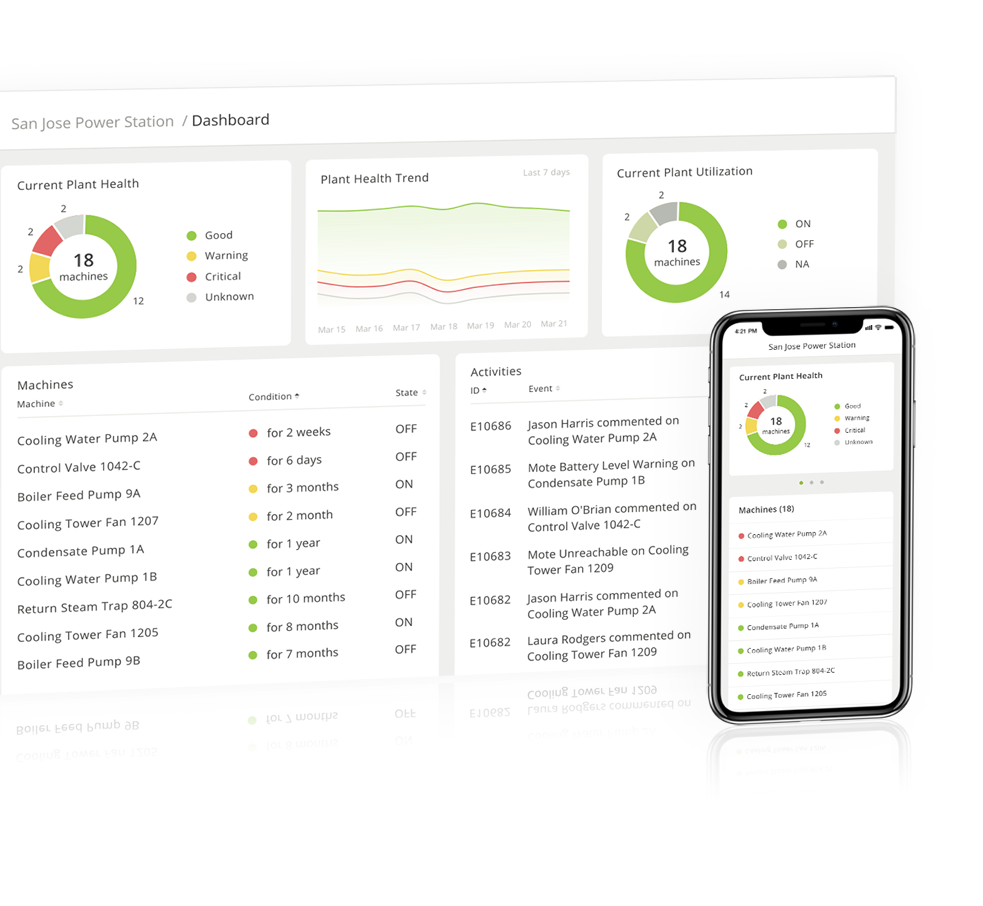

Actionable Insights

Anytime, AnywhereGet real-time alerts and insights on asset performance via Web and Mobile Apps, empowering your team to make informed maintenance decisions.

SEE HOW IT WORKS

SEE HOW IT WORKS

Thanks for subscribing - stay tuned for our next newsletter

Thanks for subscribing - stay tuned for our next newsletter