SEPTEMBER 17, 2025

When Wireless Doesn’t Work: How to Digitize Assets in Challenging Environments

DAN BRADLEY, SENIOR EXECUTIVE @ PETASENSE

Why Wireless Doesn’t Always Work

Wireless sensors have changed the game in condition monitoring, making it easier to cover more assets and collect data more often. Yet anyone who has worked in an industrial site or facility knows there are environments where wireless isn’t feasible or optimal. This includes RF-challenged areas, high-temperature zones, and cases where complex fault modes require higher-fidelity data. Through real-world case studies, we examine how alternative digitization strategies such as remote-mounted transmitters, wired sensors, or hybrid architectures can extend digital transformation to hard-to-monitor assets. These approaches offer practical ways to keep data flowing and assets visible, even when wireless isn’t an option.

The Impact of Wireless Sensors

The rise of wireless sensors has clearly transformed the condition monitoring market. Industry estimates show that wireless systems are growing at double-digit annual rates, compared to single-digit growth for legacy systems such as hardwired and portable data collectors.

This rapid growth is driven by factors such as near real-time coverage of critical assets, better use of limited expertise and resources, lower installation costs compared to hardwired systems, and in some cases broader coverage by capturing assets that run in batch mode or are normally spared. 1

While not a solution for every application, wireless plays an important and growing role in best-in-class programs. This is especially true when combined with portable data collectors and machinery protection systems, ensuring that the right technology is applied in each case. 1

Where Wireless Sensors Fall Short

Even with their rapid growth, wireless sensors aren’t a fit for every situation. In the industrial world, challenges like RF interference, extreme temperatures, or complex fault modes can make wireless impractical. Below, we break down the most common obstacles and show how they can be overcome while still delivering the benefits of a digitized solution.

Reliable Connectivity

Often, critical assets are enclosed in metal compartments that block or severely limit wireless sensor connectivity. In other cases, thick concrete walls or excessive piping can create similar barriers to signal strength. Regardless of the communication protocol, wireless sensors rely on built-in antennas to transmit data to a WiFi access point or proprietary gateway. Common examples include shrouded fans 2, air compressors enclosed for noise reduction, and paper machine dryer sections (see Figure 1).

Challenging Applications

By design, wireless sensors combine the electronics, power source, and sensing element into a single unit. Because wireless sensors are designed to minimize cost and power use, often with MEMS-based elements, they can face limitations in certain applications.

Equipment that operates at very high speeds or generates high-frequency defects (such as gearboxes, multi-stage compressors, or precision machine tool spindles) may require specialized sensors. At the other extreme are slow-speed applications, which may generate defect frequencies at very low ranges and amplitudes. These too often require specialized sensors.

Many industrial facilities have already invested in traditional piezo accelerometers, often with BNC junction boxes (see Figure 2). These setups were originally designed to connect with portable data collectors, allowing technicians to manually gather vibration readings. Rather than discarding this equipment, organizations can preserve their investment and extend its value by connecting these accelerometers and junction boxes to digitize the signal and send the data to the cloud.

Some challenging applications are location-specific. For example, very high-temperature applications above 85 degrees Celsius (185 degrees Fahrenheit) can limit wireless options, since nearly all wireless sensor batteries have strict temperature limitations. In other cases, restricted access can make it difficult to reach devices for battery replacements. And in hazardous areas with intrinsic safety requirements (ATEX Zone 0/1 or Class 1, Division 1), specialized sensors are required. While these conditions can push wireless sensors beyond their limits, they don’t have to stop digitization when the right alternatives are applied.

Beyond Vibration: Flexibility in Fault Detection

Vibration is by far the most common and often the most useful parameter for fault detection. However, in many cases vibration needs to be augmented, or even replaced, by other parameters that are better suited for detecting and diagnosing faults.

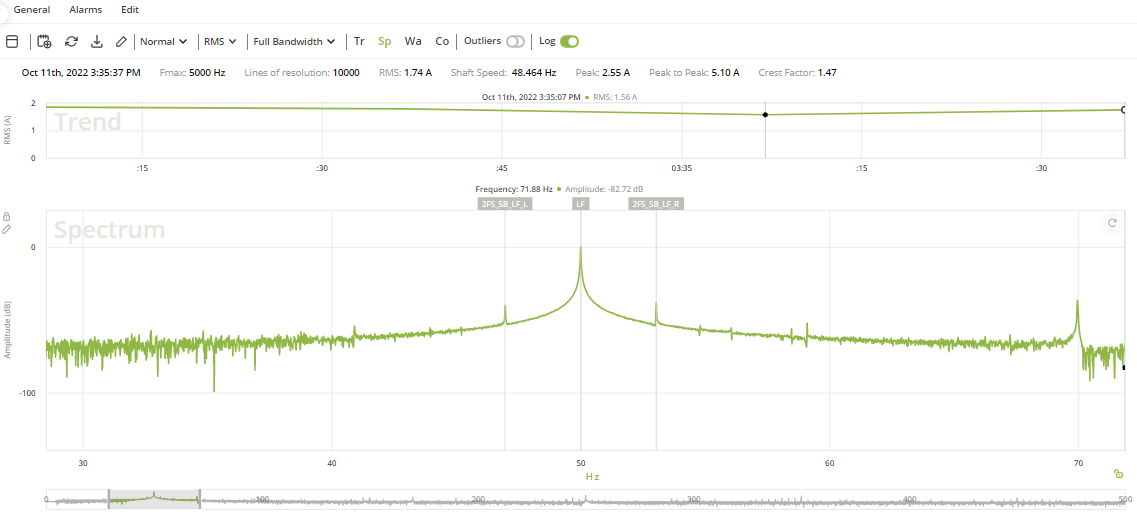

Common examples include sensors that monitor current 3 (See Figure 3), voltage, pressure, temperature, flow, and ultrasound. Being able to use existing sensors, or add economical analog sensors and digitize them, gives reliability programs a valuable level of flexibility.

A Flexible Solution to Wireless Challenges

These challenges are common across industries and in most sites with comprehensive condition monitoring programs. The ideal solution allows users to apply specific sensors for these situations, while still offering an affordable way to digitize signals and reliably send them to the cloud.

To address these challenges, wireless sensor providers have introduced the concept of wireless transmitters. These devices allow traditional wired sensors to be converted into online, real-time data collection points, extending digital coverage to assets that would otherwise be difficult to monitor.

For example, the Petasense Transmitter (TX) is a nine-channel data acquisition device that can be direct-powered or battery-operated. It supports a wide range of sensors designed to overcome the limitations described above (see Figure 4). The transmitter accepts input from traditional accelerometers as well as almost any analog sensor using 4–20 mA, 0–5 V, or 0–30 V signals. If parametric gating is required (triggered inputs for measurements), a PLC input can also be connected. The transmitter can power sensors if needed, provide signal conditioning, and then transmit data wirelessly to the plant network. For hazardous applications, it can be installed in approved enclosures that meet process requirements.

Sensors are mounted at the appropriate points with short wiring runs to a transmitter located outside the enclosure or restricted area. Devices can be stacked to expand capacity beyond nine channels when required. A local BNC output is also provided for convenient use with portable data collectors when additional measurements are needed. When combined with wireless sensors, transmitters give reliability teams the flexibility to apply the right technology for each application.

Summary

Wireless sensors have undoubtedly transformed condition monitoring, making it easier than ever to track critical assets. But as we’ve seen, wireless alone has its limits. Connectivity barriers, harsh environments, and specialized monitoring needs all create gaps that can’t be closed with a one-size-fits-all approach.

That’s where transmitters and complementary sensing technologies come in. By connecting traditional accelerometers, analog sensors, or other measurement devices to a wireless transmitter, teams can digitize signals that were once offline. This approach extends coverage to assets previously considered too difficult or costly to monitor, while still delivering data in real time.

The future of condition monitoring will not depend on a single technology. It will be shaped by the flexibility to combine the right tools for each situation. Facilities that integrate wireless sensors with transmitters gain more than just coverage. They build resilience, increase visibility, and create reliability programs that are ready to adapt to real-world challenges.

References

1. “10 Mistakes To Avoid When Implementing IIoT-Based Condition Monitoring”

2. “Revolutionizing AHU Maintenance: Case Studies on Predictive Health Monitoring”

3. “Holistic Machine Health Monitoring with Vibration and Current Signature Analysis”

About the Author

Dan Bradley is a Mechanical Engineer with 40+ years of experience in the Reliability and Condition Monitoring industry. This includes consulting, instrumentation & software design along with implementation of programs around the world in a variety of industries. He has held previous positions that include CEO of Petasense, Inc., Global Director of SKF AB Reliability Systems, and he started his career with IRD Mechanalysis, Inc.

Thanks for subscribing - stay tuned for our next newsletter

Thanks for subscribing - stay tuned for our next newsletter