DECEMBER 2, 2025

The Role of Acceptance Standards in High-Performance Reliability Programs

DAN BRADLEY, SENIOR EXECUTIVE @ PETASENSE

The Hidden Gap in Reliability Programs

Condition Monitoring programs typically incorporate alarm-based methodologies for routine equipment checks. When configured correctly, these alarms provide early warning of abnormal conditions and the onset of machinery failure. However, in practice, many organizations do not establish acceptance standards for new or rebuilt equipment. Best-in-class programs use these standards to ensure equipment is delivered in proper condition and ready to perform from day one. They also help establish accurate baselines and reduce future maintenance costs.

The rise of wireless technologies and cloud-based software now makes this process easier for OEMs, rebuilders, and end users. These tools support FAT (Factory Acceptance Testing), SAT (Site Acceptance Testing), and ongoing reliability programs by enabling consistent, cost-effective tracking from the factory floor to the installation site.

Why Acceptance Standards Are Essential

There are several important reasons to incorporate Acceptance Standards into your reliability program. In practice, both new and rebuilt equipment often arrive with issues present from day one. At one greenfield site, nearly 20 percent of equipment required remedial work identified during Acceptance Testing. New and rebuilt equipment can suffer from a range of issues before they ever go into operation, including:

• Damage during transportation or storage, such as mishandling, bearing damage from false brinelling, or improper warehouse conditions.

• Installation issues, including misalignment, improper base design, and piping strain.

• Manufacturing or rebuild defects, such as damaged bearings, defective motor rewinds, poor rotor balancing, or gear profile errors.

• Issues introduced during “asset upgrades,” which may alter OEM design and lead to unintended problems such as resonance, shifted critical speeds, bearing failures, hydraulic issues, or shaft fractures.

Without Acceptance Testing, these issues often go unnoticed until it is too late, reducing the potential service life of the equipment. Whether the equipment is placed into spares or prepared for production, these defects remain present from day one. The severity of the issue determines whether the asset functions properly, but in all cases the site ultimately inherits the problem.

How Acceptance Standards Are Defined

Acceptance Standards generally consist of two key elements. The first defines which measurements or tests should be performed and how they should be conducted. These requirements are typically independent of the instrumentation vendor. The second defines the acceptable values or limits required for a successful test.

These approaches are used across a wide range of asset types and industries, including automotive, foundries, petrochemical, mining, and power, covering equipment such as spindles, pumps, fans, gearboxes, and conveyor drives.

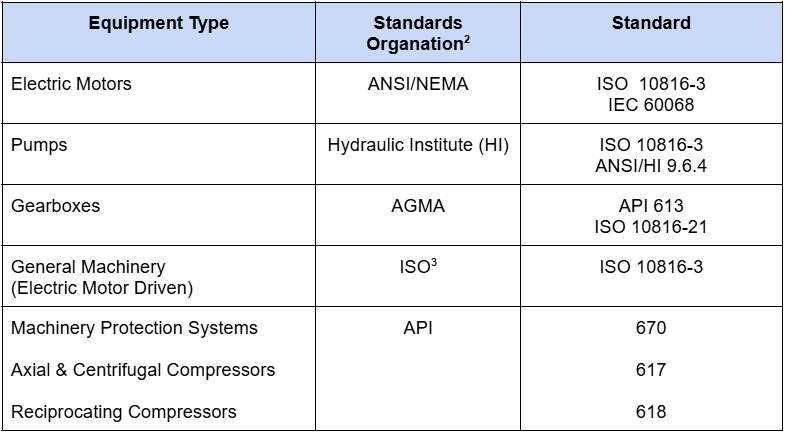

A common question is where to find the information needed to define these tests and acceptable limits. There is no universal method. In practice, many organizations rely on standards published by recognized industry groups. These standards are often asset-specific and vary based on equipment size or power rating (see Table 1). Another approach is to develop internal corporate standards based on best practices.1

For these standards to be effective, they must be incorporated into the equipment procurement process for both new and rebuilt assets. This step is critical. Without it, organizations have no basis for rejecting equipment that fails to meet the criteria. Implementing this requires coordination across Engineering, Maintenance, and Procurement.

Recommendations for Implementation

The first step in adopting Acceptance Criteria is to identify the types of equipment you want to include. This is typically based on asset type and size, though installation factors such as bases and mounting may also be relevant.

Cross-functional collaboration is essential. Engineering, Maintenance, and Procurement should be aligned on requirements, documentation, and specifications. It is also recommended to engage potential vendors early, both OEMs and rebuilders, to ensure they understand the expectations and benefits.

The next step is to determine who will perform the measurements. These assessments should be completed in two phases. Phase one occurs at the manufacturer or rebuilder before shipment, ideally on a test stand and under load. Phase two takes place after installation at the site. These measurements should be stored to establish baselines and support long-term machinery history.

Measurements may be taken by OEM or rebuilder personnel if they have the proper expertise and instrumentation. Otherwise, third-party consultants or trained site personnel can be used. The critical requirement is that whoever conducts these tests is familiar with the applicable standards and the correct use of the instrumentation.

Historically, portable data collectors were used for these measurements. However, this approach presents challenges, including inconsistent instrumentation across factory, installation, and operational stages, limited availability of skilled personnel, and difficulty storing, sharing, and tracking results across multiple databases.

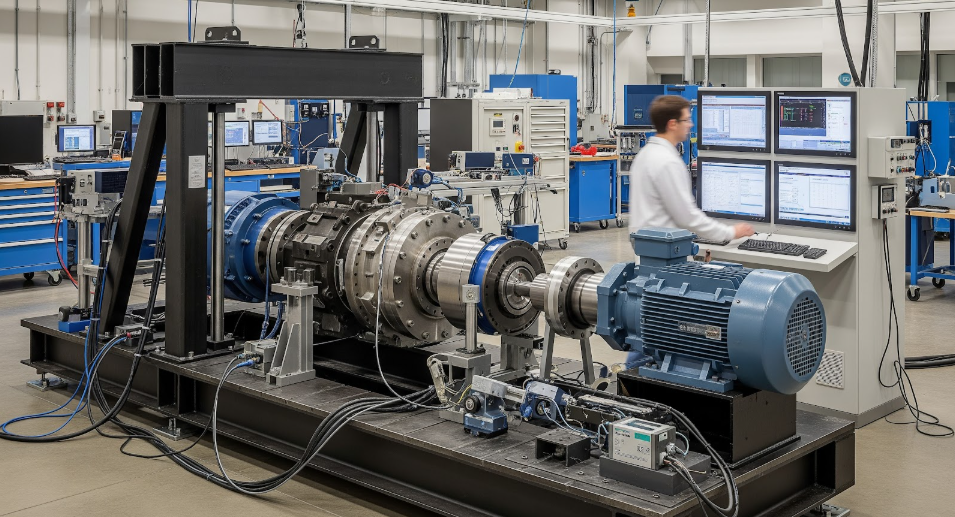

For OEM and rebuild shops, there is a growing trend toward using wireless systems on test stands and at customer sites (see Fig. 1). This greatly simplifies FAT (Factory Acceptance Testing), SAT (Site Acceptance Testing), warranty coverage, and record keeping, while enabling new value-added services. Because the data is cloud-based, it can be accessed by authorized personnel from any location at any time.

Summary

It is common for newly purchased or rebuilt equipment to have underlying issues from day one. These issues may stem from design, manufacturing, transport, or installation errors, and they often remain hidden until the equipment is pulled from storage or placed into production. When this happens, the result is unnecessary cost and avoidable downtime.

Acceptance Standards have been successfully applied across a wide range of equipment, including pumps, fans, machine-tool spindles, and gearboxes. Incorporating Acceptance Standards into a reliability program helps eliminate these early-stage faults and moves organizations toward best-in-class performance.

References

1. “General Motors Vibration Acceptance Standard. GM Specification No. v1.0 – 1997”

3. Note: ISO 10816-x covers several types of equipment including reciprocating

About the Author

Dan Bradley is a Mechanical Engineer with 40+ years of experience in the Reliability and Condition Monitoring industry. This includes consulting, instrumentation & software design along with implementation of programs around the world in a variety of industries. He has held previous positions that include CEO of Petasense, Inc., Global Director of SKF AB Reliability Systems, and he started his career with IRD Mechanalysis, Inc.

Thanks for subscribing - stay tuned for our next newsletter

Thanks for subscribing - stay tuned for our next newsletter