MAY 17, 2024

Revolutionizing AHU Maintenance: Case Studies on Predictive Health Monitoring

AKASH SHRIVASTAVA, PDM DATA SCIENTIST @ PETASENSE

The Importance of AHUs

Air Handling Units, or AHUs, are the heart of central air conditioning systems. They are pivotal in any environment that requires regulation of temperature, humidity, and particle levels, particularly in clean rooms dedicated to manufacturing and processing. AHUs play a crucial role in industries such as pharmaceuticals, electronics, and biotechnology, where maintaining stringent environmental parameters is imperative for quality assurance and regulatory compliance. As part of an HVAC system, AHUs serve as the core component responsible for circulating and conditioning air within buildings and facilities. By efficiently regulating airflow and temperature, AHUs ensure optimal comfort levels while also enhancing energy efficiency and indoor air quality in various residential, commercial, and industrial settings.

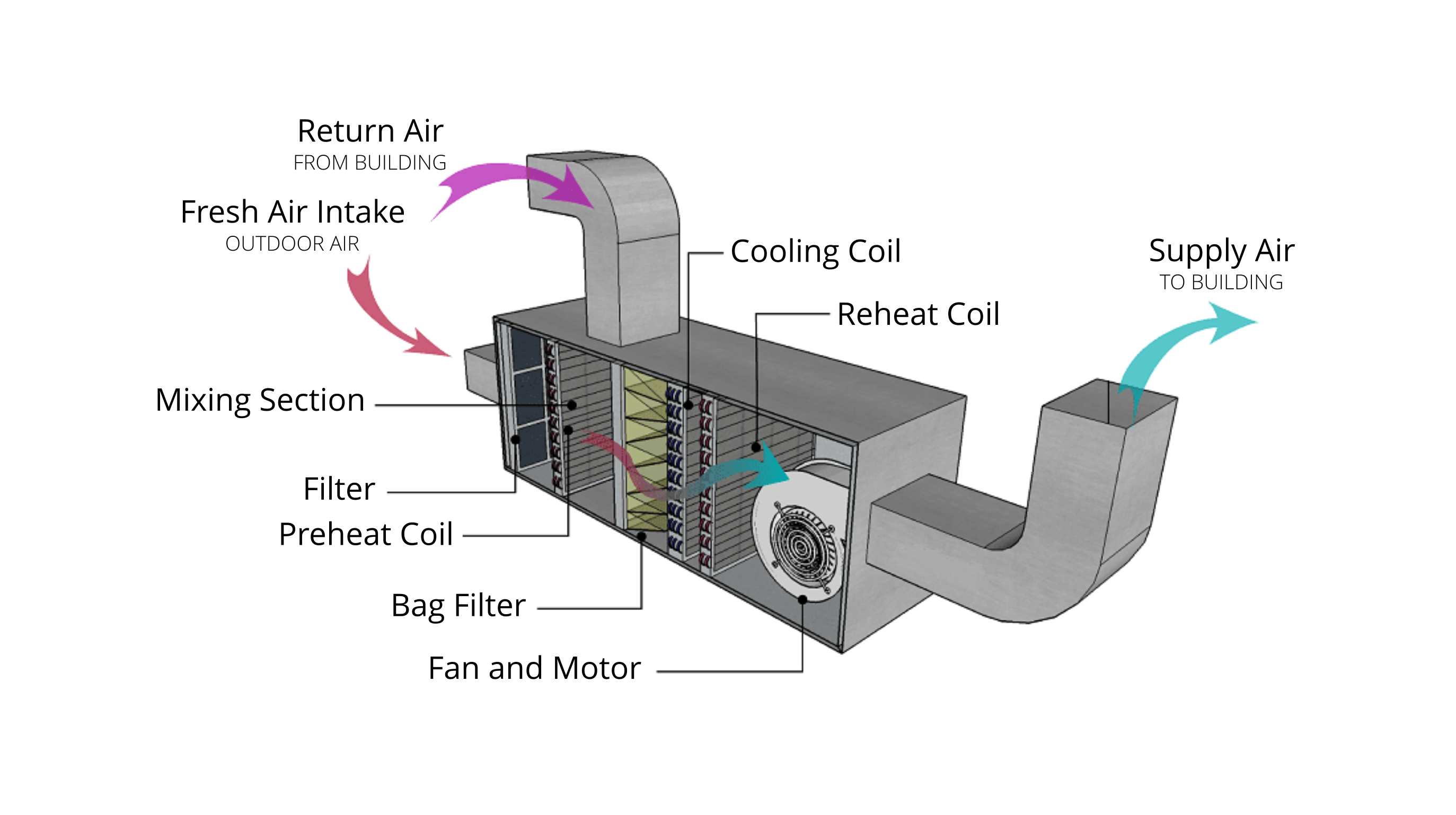

Diagram showing the flow of air through an Air Handling Unit (AHU).

Diagram showing the flow of air through an Air Handling Unit (AHU).When AHUs develop faults such as motor issues, loose belts, unbalanced fans, or dirty filters, it can lead to significant problems. In critical applications like pharmaceutical manufacturing, even minor deviations in temperature and humidity can jeopardize product quality and safety. Additionally, dirty filters or other faults can introduce contaminants, risking product integrity and potentially causing regulatory issues. These failures can result in costly production losses and unplanned downtime. To counter these risks, regular condition monitoring and predictive maintenance of AHUs are crucial to identify and address issues before they escalate, leading to reliable AHU operation and ensuring product quality in critical environments.

Modern Solutions for AHU Monitoring

AHU Monitoring presents some unique logistical challenges due to their enclosed spaces, poor or lack of wireless connectivity, and often inaccessible locations within facilities. These factors have traditionally prevented real-time monitoring and predictive maintenance for Air Handling Units.

In recent years, Industrial IoT-based monitoring solutions are solving this challenge and enabling the predictive maintenance of AHUs and other equipment alike. These systems integrate wireless sensor technologies and advanced data analytics, enabling real-time monitoring of crucial machine health parameters such as vibration, temperature, motor current, differential pressure and other condition monitoring or process parameters for rotating machines. This proactive approach empowers facility managers and reliability engineers to identify potential issues early on before they escalate into catastrophic events, avoiding unexpected downtime, production waste and costly repairs. However, not every wireless monitoring system is created equal and it’s important to distinguish the key differences between AHU monitoring solutions to identify the best solution for your applications.

Petasense’s ARO System (for Asset Reliability and Optimization) accomplishes AHU monitoring with a product called the Transmitter (or TX), a wireless sensor input module that takes in wired sensors and transmits the data wirelessly for real-time analysis. This technology enables multi-parametric condition monitoring for AHUs and other industrial monitoring applications, by allowing for various types of industrial sensors to be integrated, such as vibration, ultrasound, motor current, differential pressure. As a solution for enclosed equipment, the Transmitter can be installed on the exterior of an Air Handling Unit for optimal wireless communication, while the sensors can be wired into the AHU housing and mounted close to the bearing locations. Additionally, since many Air Handling Units operate with a VFD, or variable frequency (speed) drive, Petasense monitors the magnetic flux of the AHU motor to determine its running speed, in order to correlate the variable operation of the AHU to its vibration and temperature trends. This robust approach ensures that insights are accurate and reliable, enabling proactive maintenance to maximize AHU uptime.

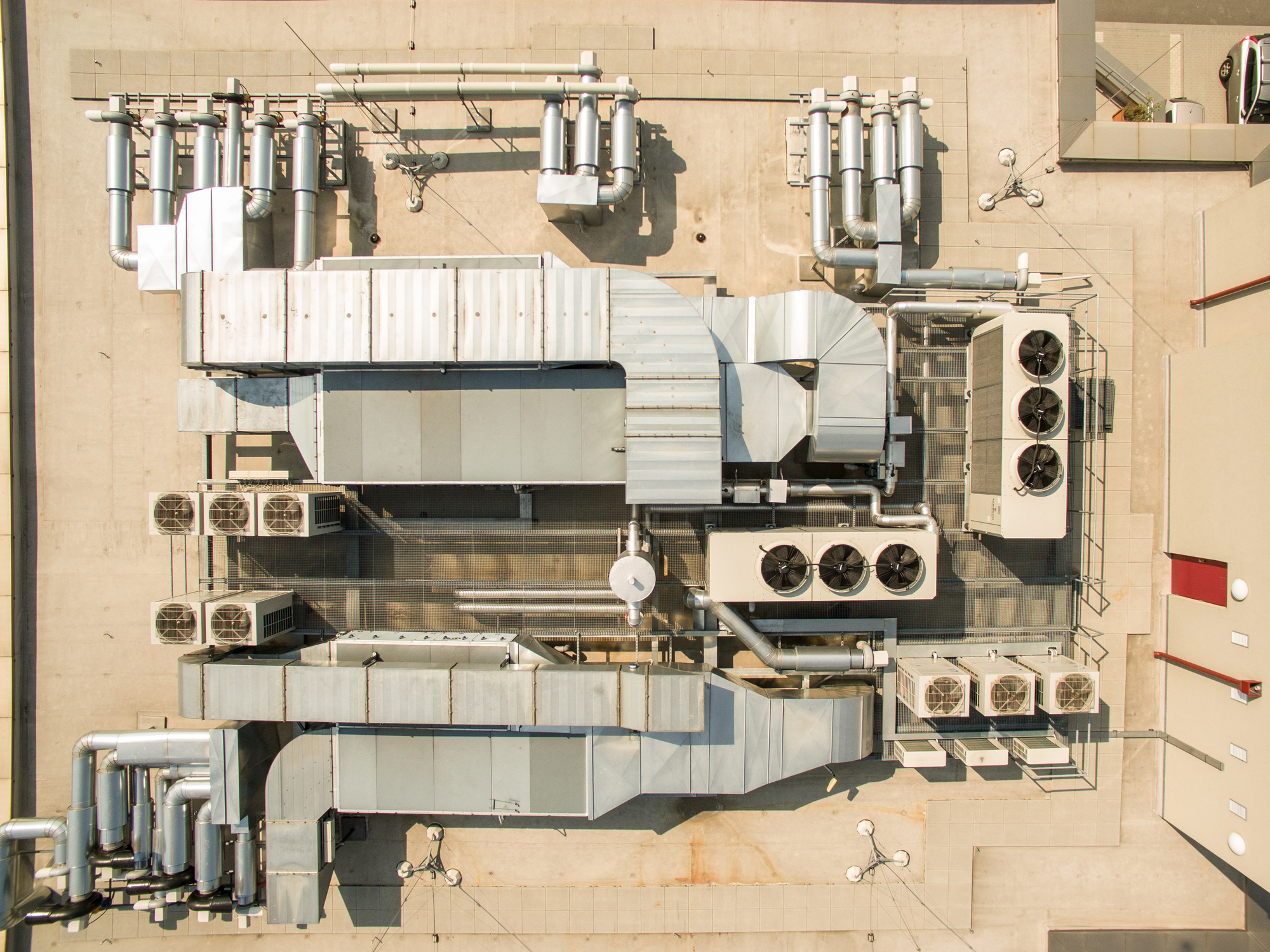

The Petasense Transmitter can be installed on the exterior of an Air Handling Unit for optimal wireless communication, while the sensors can be wired into the AHU housing and mounted close to the bearing locations.

In this article we’ll share some field case studies from real users of the Petasense ARO system, showcasing the transformative impact of wireless AHU monitoring. We will delve into fault findings and highlight the seamless integration of the technology into traditional maintenance workflows. Through the lens of these case studies, we will explore how IIoT-based condition monitoring empowers facility managers and reliability professionals to make informed decisions, mitigate risks, and uphold the integrity of critical HVAC infrastructure.

Case Study 1

In a critical environment like a pharmaceutical plant, ensuring the smooth operation of equipment is paramount. In this case study, we focus on an AHU supply fan that helps maintain optimal clean room conditions within a pharmaceutical R&D center. The fan, driven by a 40hp, 4-pole motor with grease-lubricated bearings, plays a primary role in controlling air quality and temperature regulation. Shortly after installing the wireless monitoring system in the facility, an anomaly was detected within the AHU supply fan.

Petasense’s diagnostic insights use a rule-based system to review trend and spectrum charts and help automate the identification of particular fault modes in various asset classes. In this case, Petasense analysts were able to quickly verify the abnormal vibration patterns indicative of an early stage bearing defect in the motor of the AHU supply fan. Leveraging parameters such as Acceleration RMS, demodulation (also known as envelope), and crest factors, the system accurately assesses the severity of the fault and formulates targeted maintenance recommendations, enabling prompt corrective action.

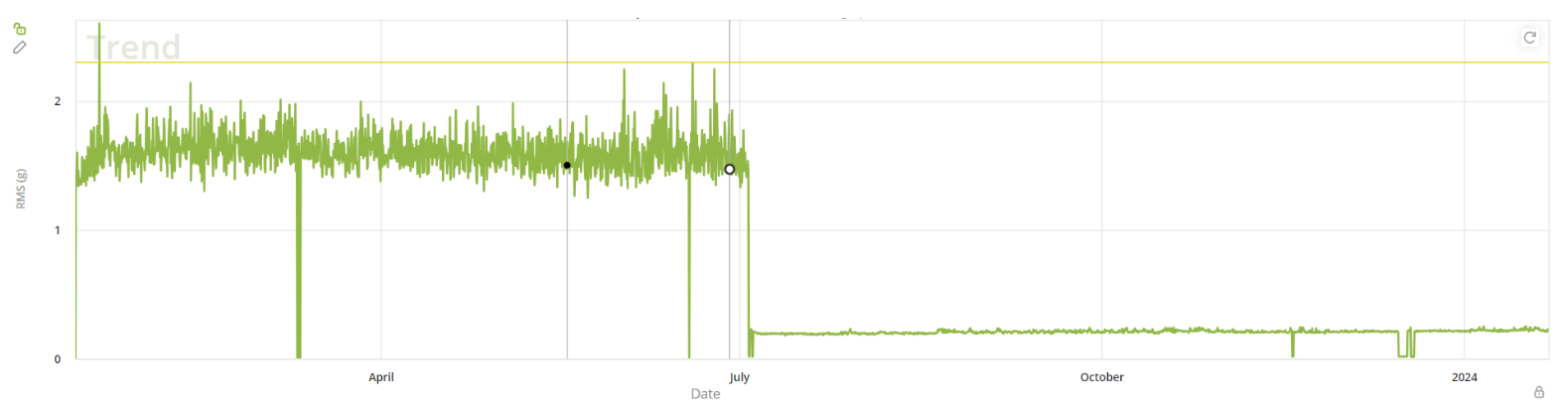

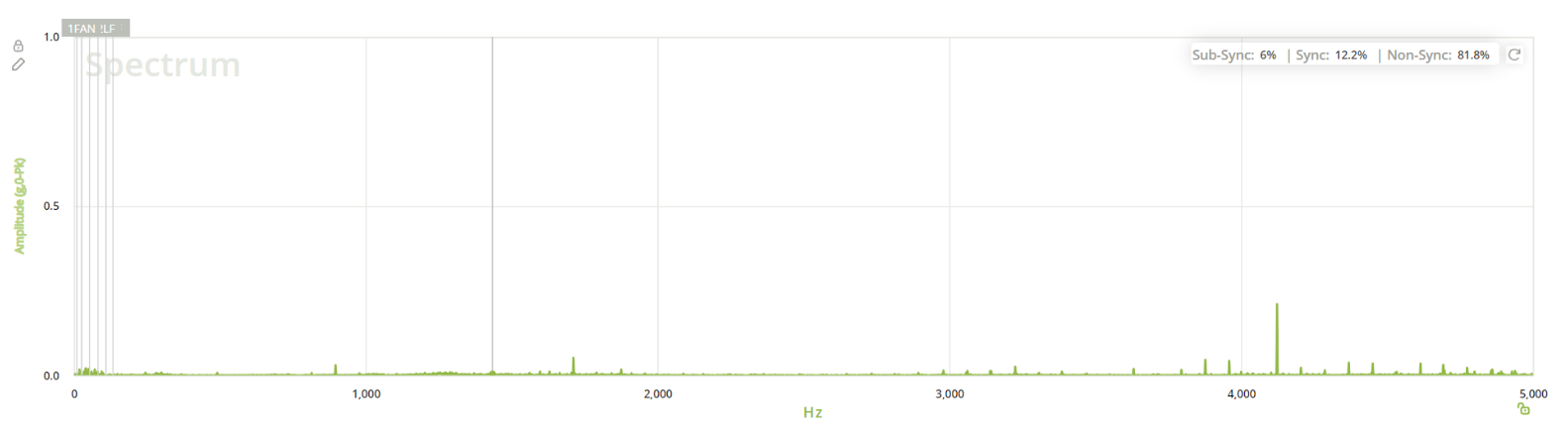

Figure 1.1: Overall Acceleration trend shows the dramatic reduction of vibration after maintenance is completed. Vibration levels dropped from 1.6 g to 0.2 g post-maintenance.

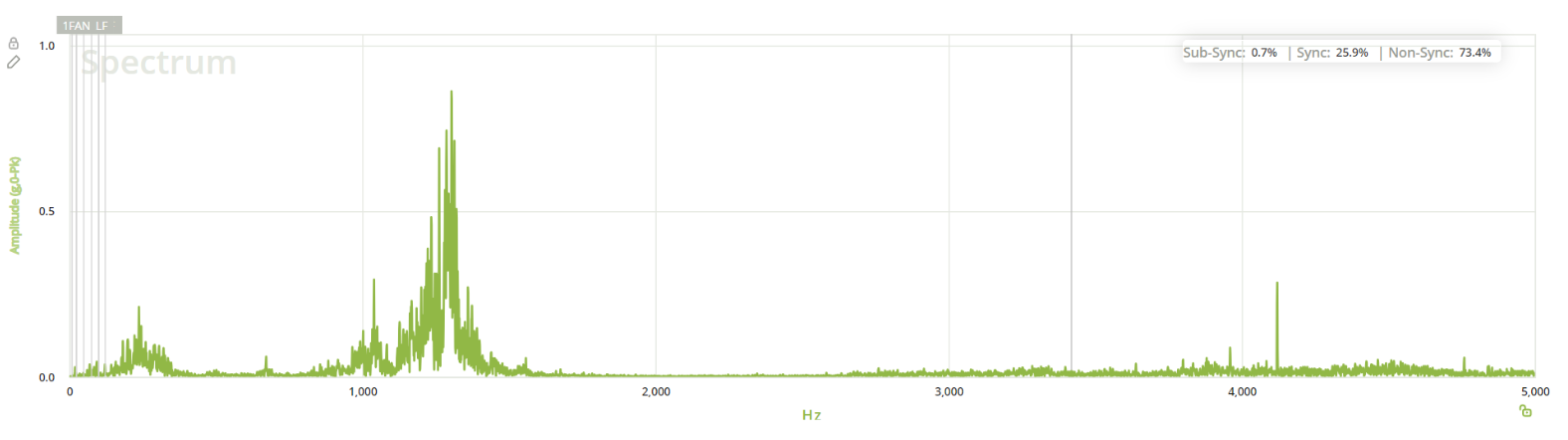

Figure 1.1: Overall Acceleration trend shows the dramatic reduction of vibration after maintenance is completed. Vibration levels dropped from 1.6 g to 0.2 g post-maintenance. Figure 1.2: Acceleration spectrum before maintenance.

Figure 1.2: Acceleration spectrum before maintenance. Figure 1.3: Acceleration spectrum after maintenance.

Figure 1.3: Acceleration spectrum after maintenance.

Case Study 2

In this case study, we examine a scenario at a manufacturing facility of a large pharmaceutical company, where the facility identified a loose mounting/foundation issue on an Air Handling Unit by leveraging wireless monitoring from Petasense.

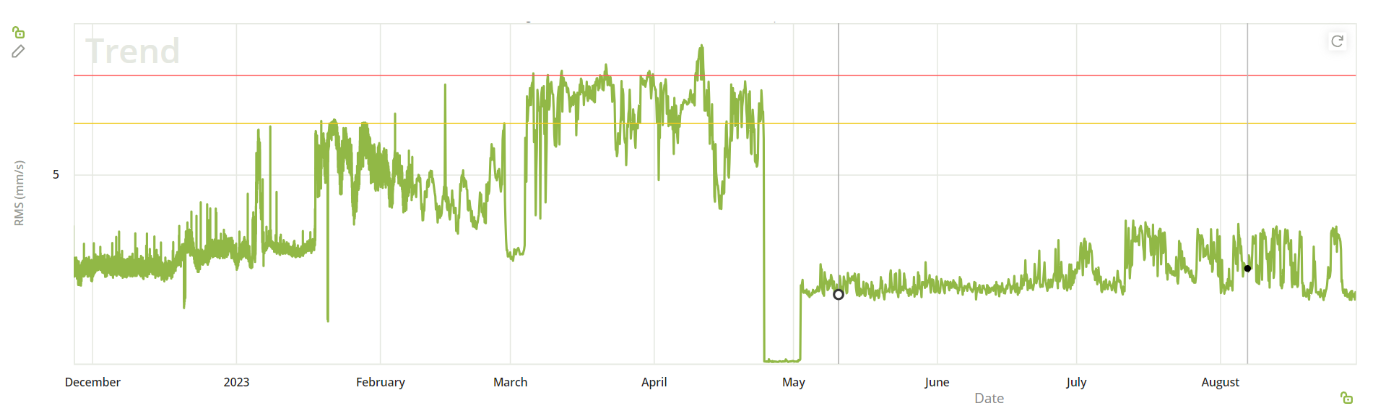

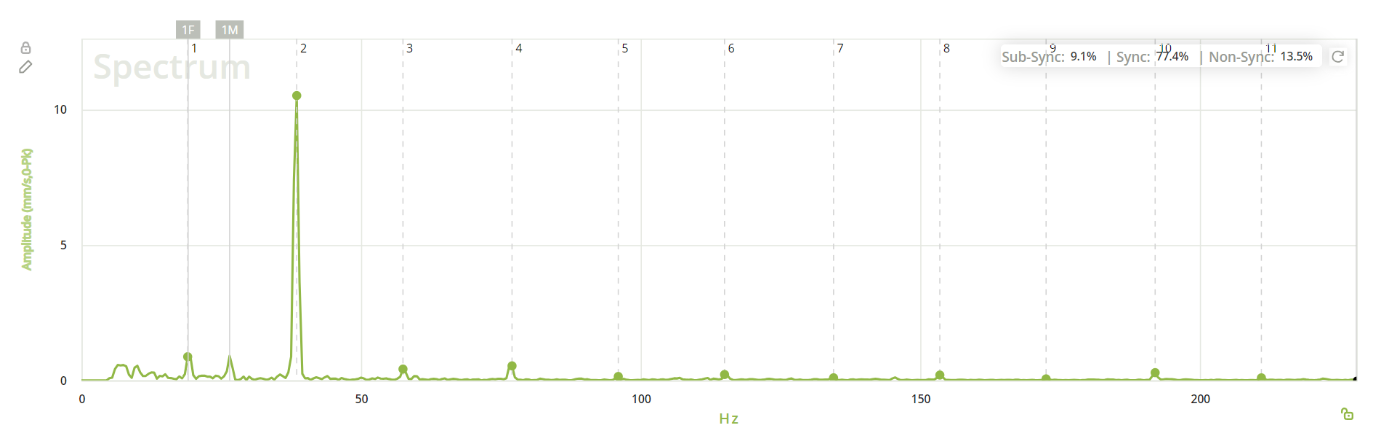

In January 2023, the site reliability team received an automated notification from the system that one of their critical AHUs had exceeded a warning alarm threshold for vibration (RMS velocity). The trending data indicated a concerning degradation in the condition of the AHU, including a noticeable increase in vibration baseline that was progressively worsening. The Vibration spectra revealed that the increase was prominent at 2X the fan speed frequency along with a rise in fan running speed harmonics. These trends strongly suggested the presence of looseness and/or wear in the mounting bolts or foundation of the AHU, posing a potential threat to its structural integrity.

Figure 2.1: Fan drive end overall (RMS) vertical velocity trend. Vibrations trended upwards for several months, reducing and stabilizing after the recommended maintenance was completed.

Figure 2.1: Fan drive end overall (RMS) vertical velocity trend. Vibrations trended upwards for several months, reducing and stabilizing after the recommended maintenance was completed.To address the detected issue, an immediate inspection was recommended to be scheduled at the site as soon as feasible. Petasense analysts recommended the following process:

1. Perform a comprehensive check of all bolting mechanisms to ensure they are adequately secured

2. Perform a careful examination to identify any signs of damage or deterioration

3. Verify the integrity of the fan bearing supports and inspect the sheaves for any indications of damage

4. Check and correct alignment belt condition and tension to ensure the AHU’s optimal functioning.

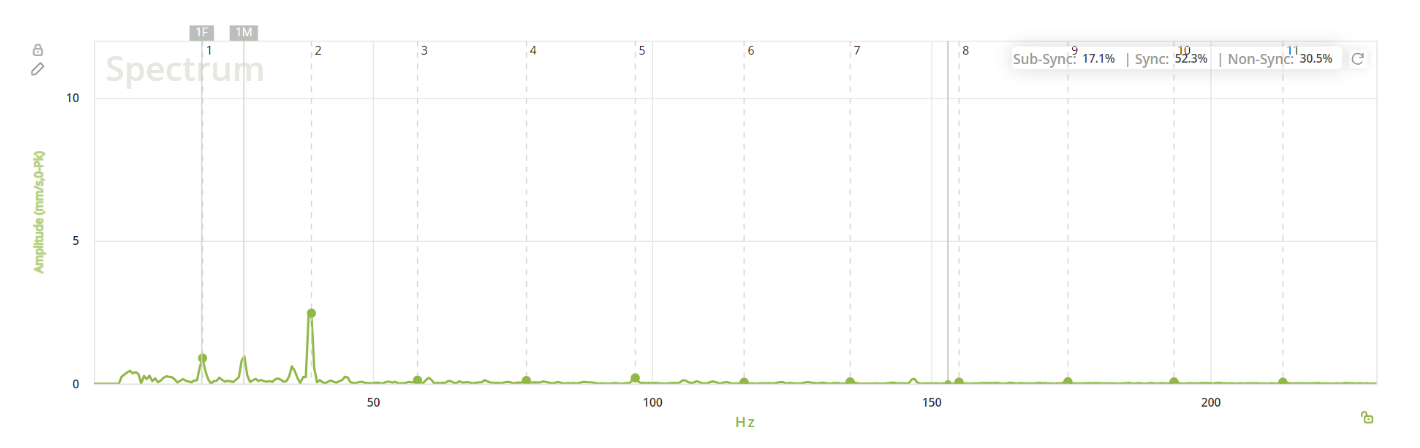

Upon inspection, issues were detected in the belt sheaves. It was concluded that over time the sheaves had been damaged due to misalignment or a combination of faults. The replacement of the motor and fan sheaves resolved the AHU’s vibration problem. This successful resolution validates the importance of proactive maintenance and timely interventions in ensuring the reliability and longevity of AHU systems.

Figure 2.2: Velocity spectrum before maintenance. Predominant 2X peak indicating looseness in the mounting or foundation of the AHU.

Figure 2.2: Velocity spectrum before maintenance. Predominant 2X peak indicating looseness in the mounting or foundation of the AHU. Figure 2.3: Velocity spectrum after maintenance.

Figure 2.3: Velocity spectrum after maintenance.

Case Study 3

This case takes place at a critical facility for a global science and technology company. The facility happened to have a robust WiFi network throughout, so Petasense’s Vibration Motes were installed to wirelessly monitor vibration, temperature and magnetic flux of critical HVAC equipment. When monitoring variable speed assets, like AHUs, magnetic flux can be used to monitor the running speed of a motor in order to correlate the asset’s variable operation to the trends in vibration and temperature.

Figure 3.1: AHU motor with Petasense Vibration Mote installed at the drive end.

Figure 3.1: AHU motor with Petasense Vibration Mote installed at the drive end.The Petasense system alerted the site team of elevated vibration levels, indicating a potential belt issue with one of the facility’s AHU fans. The system identified dominant belt frequencies and harmonics, including particularly dominant 2X belt frequencies in the vibration spectra.

The primary recommendation to the site team required a detailed inspection of the belt system to assess wear, tension, and alignment irregularities. Maintenance personnel were advised to take necessary corrective measures to restore the belt condition. By prioritizing proactive maintenance measures, the site reliability team addressed the underlying causes of the vibration anomaly, thereby minimizing the risk of potential breakdowns and ensuring the AHU continued operating smoothly.

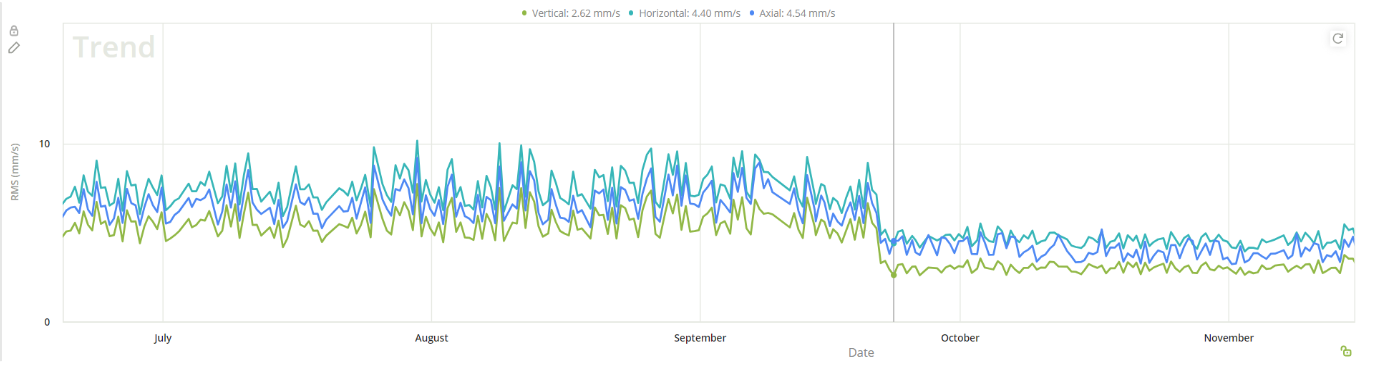

Figure 3.2: Motor drive end overall (RMS) tri-axial velocity trend. Vibrations reduced in all three axes post-maintenance.

Figure 3.2: Motor drive end overall (RMS) tri-axial velocity trend. Vibrations reduced in all three axes post-maintenance.Following the implementation of recommended maintenance measures, vibration levels were reduced. Post-maintenance assessments indicated a notable reduction in vibration, confirming the effectiveness of the proactive maintenance in rectifying the belt issues and ensuring the AHU’s reliability and longevity.

Case Study 4

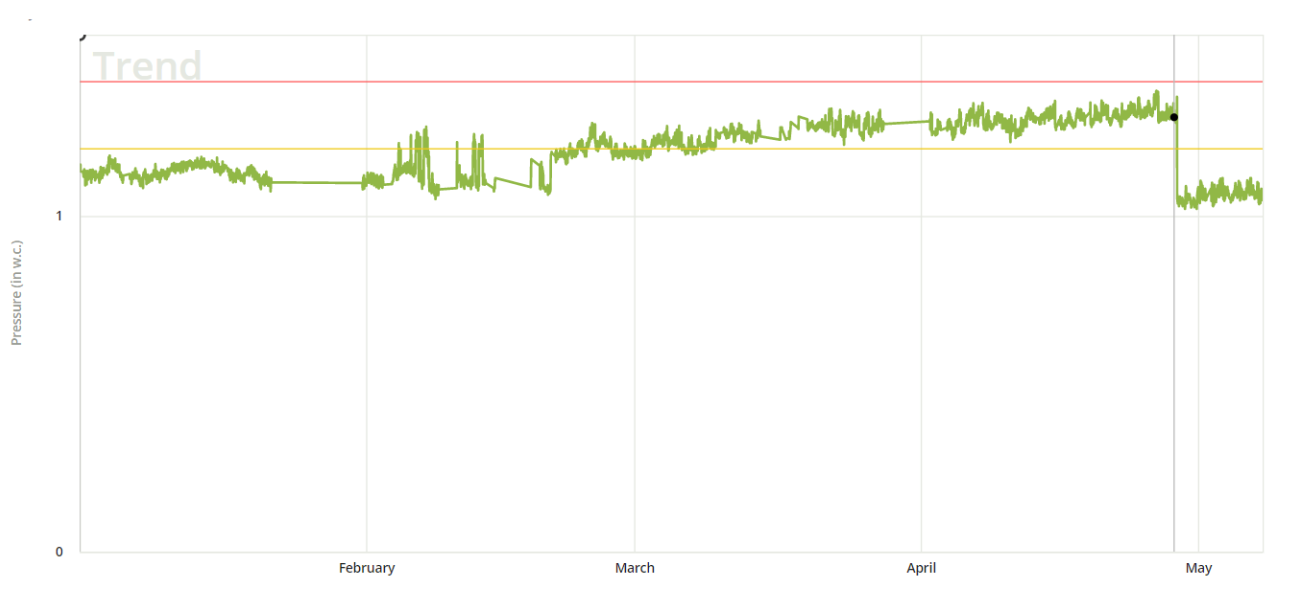

In this example, we present a case from a biotechnology company where wireless condition monitoring led to the detection of a clogged AHU filter. In this case, the Petasense Transmitter (TX) was utilized to monitor both vibration and differential pressure for a more holistic view of AHU health. The issue came to light when a notable increase occurred in both differential pressure and vibration at the motor drive end, triggering a notification for the maintenance to perform an inspection. Upon further investigation, the site operations manager stated, “the filter was choked with dust due to construction work going on in the area and would need to be changed early”.

Figure 4.1: Motor drive end overall (RMS) tri-axial velocity trend. Vibrations reduced in all three axes post-maintenance.

After following the recommended corrective actions, including a thorough filter cleaning and an inspection to ensure proper motor alignment and belt tension, the levels of differential pressure and vibration on the AHU returned to optimal levels.

Conclusion

In summary, the health monitoring of Air Handling Units (AHUs) is paramount for maintaining optimal functionality and reliability of operations across nearly every industry. Common defects such as bearing failures, mounting irregularities, and belt deterioration, can significantly impact AHU performance if left undetected. Through these case studies, we have demonstrated the efficacy of Industrial IoT-based monitoring in proactively identifying and addressing potential faults within AHUs before they escalate into catastrophic failures.

Industrial IoT-based solutions offer several key advantages when it comes to AHU monitoring. Firstly, they provide access to real-time insights, allowing you to monitor AHU and other machine health remotely from any location with internet access. This accessibility ensures constant oversight, enabling timely responses to any issues that may arise. Moreover, wireless monitoring operates 24/7, providing continuous surveillance and peace of mind without the time-based limitations of traditional AHU monitoring methods. Additionally, wireless systems typically require lower implementation costs compared to hardwired alternatives, as they eliminate the need for extensive wiring and local infrastructure. This cost-effectiveness of wireless monitoring helps build the business case for justifying continuous condition monitoring of AHUs and other HVAC machinery.

By harnessing the power of Industrial IoT-based solutions, such as wireless sensors and predictive machine health analytics, organizations can embark on a journey towards proactive AHU maintenance, to optimize equipment reliability and enhance operational efficiency.

Thanks for subscribing - stay tuned for our next newsletter

Thanks for subscribing - stay tuned for our next newsletter