OCTOBER 7, 2025

The Power of Magnetic Flux Combined With Vibration Monitoring

AKASH SHRIVASTAVA, PDM DATA SCIENTIST @ PETASENSE

The Rise of Multi-Parameter Monitoring

Over the past decade, sensing technologies have advanced significantly, ushering in an era of intelligent, connected, and context-aware condition monitoring. A notable innovation in this space is the emergence of wireless multipurpose vibration sensors capable of capturing not only vibration but also complementary parameters such as temperature and magnetic flux density. These multi-parameter sensors enable analysts to understand not just how a machine is behaving, but also why.

Vibration remains the most widely used condition monitoring technique in machinery diagnostics. However, vibration patterns can be influenced by a wide range of external and internal factors, including load changes, speed variations, and process fluctuations. When vibration data are captured under such dynamic conditions, analysis becomes significantly more challenging. Without contextual information, it can be difficult to determine whether a change in vibration levels reflects a developing fault or simply a shift in operating state. This challenge is especially pronounced in remote monitoring environments where steady-state operation is the exception, not the norm.

The Role of Magnetic Flux

This is where additional sensing modalities such as magnetic flux sensing become invaluable. Flux density measurements, for example, can be used to infer a pump’s operating speed, estimate load, and detect on/off state. These operational insights complement vibration data, helping analysts distinguish between normal variations and emerging faults. For instance, a sudden rise in vibration may raise concerns, but when correlated with a change in speed or load inferred from flux data, it might simply indicate normal process behavior under different operating conditions.

By combining and correlating vibration, flux, and speed, analysts can interpret trends and spectral patterns with greater confidence. This multi-parameter approach enhances remote monitoring capabilities, enabling earlier fault detection, fewer false alarms, and better-informed maintenance decisions.

In the following sections, we explore how the fusion of magnetic flux sensing and vibration monitoring deepens motor and pump condition analysis, providing examples of how this combination has clarified machine behavior and improved diagnostic accuracy in real-world scenarios.

Why Magnetic Flux Matters in Condition Monitoring

While vibration data provides essential insight into the mechanical behavior of rotating machines, magnetic flux sensing adds valuable context by helping monitor operating conditions such as speed and load, as well as potential motor faults. It serves as a complementary signal that enables better interpretation of vibration data and, in some cases, reveals issues that vibration alone might miss or detect only in later stages.

In industrial motors, total magnetic flux consists of main and leakage components. The cast-iron or steel housing blocks most of the alternating-current flux due to eddy currents, but some leakage occurs because the metal is an imperfect conductor. Faults cause asymmetrical flux distribution, increasing leakage flux and producing fault-specific harmonic patterns. These flux changes provide vital insight into machine health, especially for faults undetectable by vibration alone. This makes flux analysis a valuable tool for early fault detection and improved diagnostic confidence.

Understanding Machine Operating States

Magnetic flux is particularly effective in identifying key operational states of electric motors and pumps. By monitoring flux level and spectrum, one can determine:

• Machine ON/OFF state

• Motor operating speed

• Load conditions

• Machine startup or transient events

This information is critical in environments where machines operate under variable conditions, such as those driven by variable frequency drives (VFDs) or intermittent duty cycles. Flux-derived speed calculations can also be leveraged to automatically apply appropriate baselines and alarm thresholds. By distinguishing between operating states, the system ensures that vibration alerts are only triggered when deviations are abnormal for a given speed or load condition. This reduces false positives and improves diagnostic accuracy.

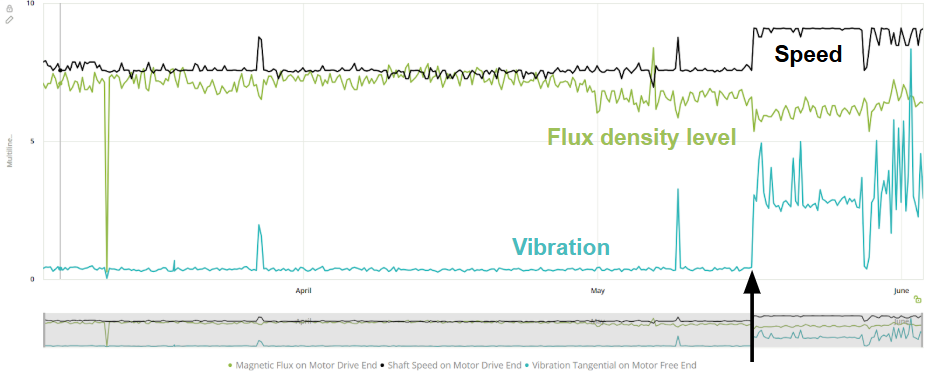

If a sudden increase in vibration is observed, flux data can help determine whether it was triggered by a change in speed or load, or by an actual fault. For example, in a three-pump system, the speed of one pump suddenly increased to its rated value due to an operational demand change. This resulted in higher vibration levels (see Figure 2). If only vibration data were available, the sudden amplitude shift could have triggered a false alarm or unnecessary inspection. However, by correlating flux-derived speed and load data, analysts confidently identified the change as an operational adjustment rather than a developing fault.

Detecting Motor Faults Through Magnetic Flux Analysis

Magnetic flux sensing has gained increasing attention in academic research as a promising technique for diagnosing faults in electric machines, particularly as an alternative to Motor Current Signature Analysis (MCSA). A combination of flux and vibration analysis provides a more accurate foundation for fault diagnosis than vibration data alone, since flux offers direct insight into the electromagnetic behavior underlying those vibration patterns.

Several studies have shown that flux signals, especially when captured close to the motor, can carry fault-specific signatures similar to those found in current signals. However, there are still few commercial implementations or real-world case studies using flux-based diagnostics, making it an emerging area in industrial condition monitoring. The advantage of magnetic flux sensing lies in its ability to offer direct insight into a motor’s electromagnetic behavior without requiring invasive connections or current clamps.

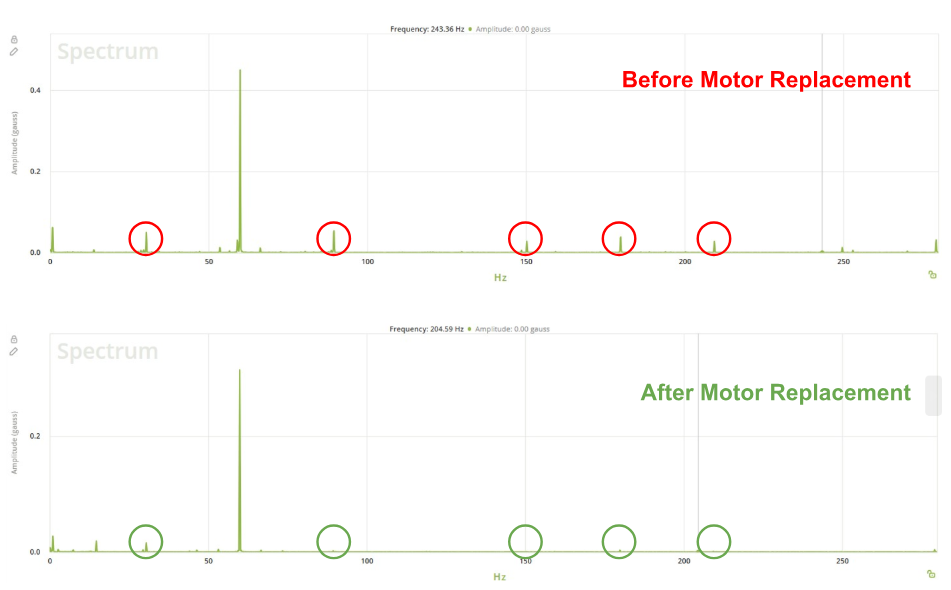

In one case, a motor driving a pump eventually seized during operation and required replacement. Prior to failure, vibration data showed only subtle and inconclusive changes, offering no clear indication of a developing issue. However, analysis of the flux spectrum revealed distinct modulating components that indicated a potential electrical fault not present in a healthy motor (see Figure 3).

After the motor was replaced and the system restored, follow-up flux measurements confirmed the diagnosis. The modulating components disappeared, and the spectrum returned to a clean, nominal profile, validating the effectiveness of flux analysis in detecting early-stage electrical problems.

Closing Thoughts

As industrial machines operate under increasingly dynamic conditions, relying solely on vibration data can sometimes lead to misinterpretation or missed faults. The integration of magnetic flux sensing with vibration monitoring provides essential context by revealing machine speed, load, and operational states. This multi-parameter approach allows analysts to distinguish between process-driven changes and true mechanical or electrical issues.

The examples discussed demonstrate how flux analysis can uncover early signs of electrical faults, such as winding asymmetries, that may go undetected in vibration data alone. By combining these sensing modalities, organizations can improve diagnostic accuracy, reduce false alarms, and make better-informed maintenance decisions.

As sensing technology continues to advance, magnetic flux is proving to be a valuable complement to traditional condition monitoring methods. When paired with vibration data, it provides the clarity and confidence needed to fully understand machine behavior and maintain optimal reliability.

Thanks for subscribing - stay tuned for our next newsletter

Thanks for subscribing - stay tuned for our next newsletter