JANUARY 8, 2026

How Mobile Devices Unlock the Full Potential of Wireless Condition Monitoring

DAN BRADLEY, SENIOR EXECUTIVE @ PETASENSE

Bringing Condition Monitoring to the Point of Work

The proliferation of mobile devices has empowered workers in the field in many different ways. Tablets and smartphones now support operator inspections, provide access to digital work orders, and offer on-demand views of equipment health. They also play an important role in wireless condition monitoring systems, where handheld devices are commonly used to configure and commission newly installed sensors.

However, many teams stop there.

What often goes unnoticed is that these same mobile devices can be leveraged for much more than sensor setup. They can support ad hoc troubleshooting, provide instant access to asset health history, and enable quick machinery health checks, even on equipment that is not yet part of a formal condition monitoring program.

When used intentionally, mobile devices do more than simplify wireless sensor deployment. They help turn data into faster decisions at the point of work.

Role of Mobile Devices in Cloud-Based Monitoring Systems

Typical portable devices used in industrial environments include smartphones and tablets. In wireless condition monitoring systems connected to the cloud, these devices have traditionally been used primarily for sensor provisioning and initial network configuration. However, their role can extend far beyond these basic setup tasks.

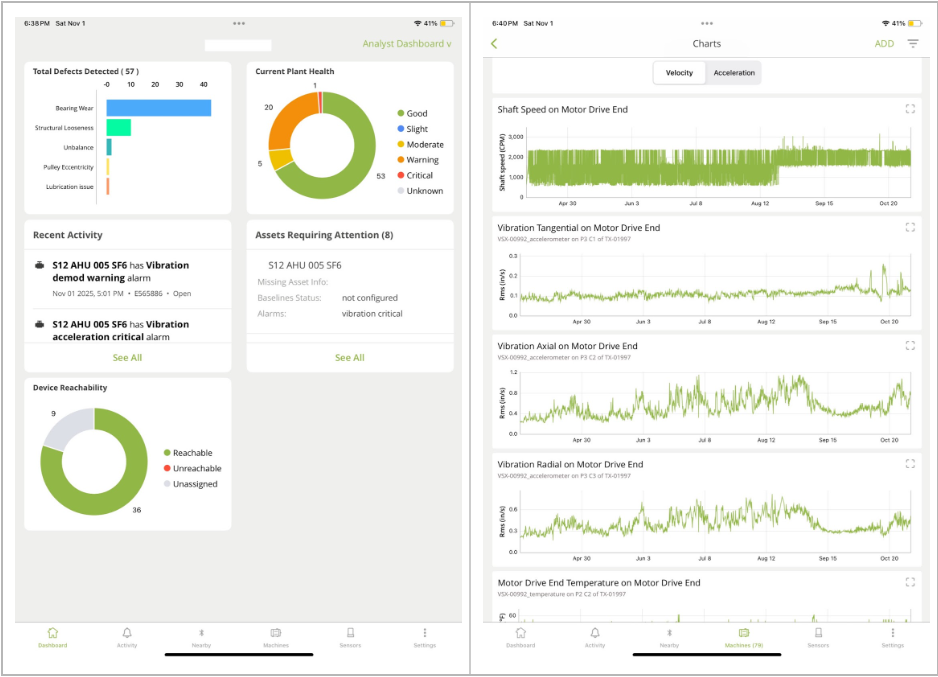

Modern platforms from established providers such as Petasense now enable mobile devices to access virtually all machinery health data and historical trends directly from the field. Maintenance and reliability teams can view asset health summaries, alarm status, and trend data in real time from a smartphone or tablet (See Figure 1).

This capability empowers mobile workers to quickly review critical asset information at the point of inspection and, when needed, dive deeper into diagnostics using interactive charts and visualizations. As a result, informed decisions can be made immediately, without returning to a control room or desktop workstation.

1. On-Demand Measurements Using a Relocatable Wireless Sensor

There are situations where a piece of equipment is not permanently instrumented, but site personnel observe abnormal noise, vibration, or operating behavior. In these cases, it can be valuable to temporarily mount a wireless sensor on the machine to obtain an immediate indication of vibration severity and potential fault sources. This approach can be used for ad hoc investigations as well as structured, route-based data collection programs where assets are periodically assessed without permanent instrumentation. The collected data can then be uploaded to the cloud for additional review and comparison.

A similar approach is useful when a permanently installed sensor has triggered an Event Notification or Alarm, but additional context is required to confirm the root cause. While fixed triaxial wireless sensors provide a large amount of information, moving a sensor to different locations on the same machine can help isolate the origin of the issue. For example, when an online system identifies a looseness condition, it may not be immediately clear whether the looseness originates at the bearing cap, the mounting interface, or the base. By collecting multiple measurements near mounting faces and structural interfaces, the source of the looseness can be positively identified, as shown in Figure 2.

When multiple wireless sensors are temporarily mounted across a machine train, peer-to-peer synchronization enables time-aligned measurements. This improves diagnostic accuracy for issues such as looseness, misalignment, and resonance by ensuring vibration data is captured under the same operating conditions.

2. In-Field Sensor Reconfiguration and Context Capture

Mobile devices enable technicians to reconfigure sensor settings directly in the field. In cases where a potential issue is suspected, measurement parameters such as collection frequency can be adjusted on demand to capture higher resolution data without waiting for a return to the control room or engineering workstation.

In addition to vibration data, mobile devices play an important role in capturing contextual information. Photos can be taken during initial asset setup to document sensor placement and machine configuration, and later during troubleshooting or repair activities to log observed conditions and corrective actions. This visual context becomes part of the asset history and supports more effective analysis, documentation, and knowledge transfer across teams.

3. Offline Data Collection in Remote or Disconnected Locations

Mobile devices also support offline measurement workflows in select wireless condition monitoring platforms designed for disconnected environments. In some locations, machinery is installed in areas without WiFi coverage and with limited or nonexistent cellular service. In these cases, measurements can be triggered directly from a mobile device using Bluetooth communication with the wireless sensors. Multiple measurements can be gathered and stored locally on the device while the user completes a data collection route. This capability allows teams to collect high quality vibration data using the same wireless sensors and analysis workflows, regardless of whether continuous network connectivity is available at the asset location.

Once the route is complete and the user returns to an area with network connectivity, the stored measurements can be uploaded in a batch to the cloud for analysis and trending. This approach enables consistent condition monitoring without requiring permanent network infrastructure at every asset location.

One example of this workflow comes from a power generation site operating remote transformer oil pump systems with no cellular coverage. These assets are visited only once or twice per year. During each visit, technicians transfer data from installed wireless sensors to a mobile device and later upload the measurements to the cloud once connectivity becomes available. The same approach applies to remote and hard to reach assets across mining, oil & gas and many other industries.

How to Leverage Mobile Devices in Condition Monitoring

One of the key advantages of incorporating mobile devices into a condition monitoring program is ease of use. Mobile applications are designed to be intuitive, requiring minimal training and configuration to operate effectively in the field. Access is typically profile based, which helps ensure that capabilities are aligned with user roles and reduces the risk of unauthorized use.

In many modern condition monitoring platforms, mobile functionality is included as part of the core system rather than offered as a separate add on. Just as with cloud based software, mobile applications continue to evolve through regular updates that expand functionality and improve usability. These ongoing enhancements are steadily narrowing the gap between traditional online analysis tools and portable, field based workflows.

Despite these capabilities, many organizations still associate mobile devices primarily with initial installation and system onboarding. As a result, they often underutilize the broader functionality available to them. To fully realize the value of a wireless condition monitoring system, it is strongly recommended that users explore the full range of mobile features and discuss available capabilities with their system provider or local administrator.

Key Takeaways

Mobile devices can play a significantly broader role in wireless condition monitoring programs than they are often given credit for. While many organizations primarily use mobile devices for initial installation and onboarding, modern systems enable far deeper interaction with machinery health data directly in the field.

Common use cases include collecting on-demand measurements, supporting route-based programs for temporarily instrumented assets, and performing advanced troubleshooting to narrow down both the type and location of vibration related issues. Mobile devices also enable offline data collection, in-field sensor reconfiguration, and improved documentation through contextual photos and asset records, extending condition monitoring workflows beyond always connected environments.

To fully realize these benefits, users are encouraged to explore the mobile capabilities available within their condition monitoring platform and understand how they can be applied across day-to-day maintenance and reliability activities. For more information, users should review the capabilities available within their existing condition monitoring platform and consult internal reliability or system administrators as needed.

About the Author

Dan Bradley is a Mechanical Engineer with 40+ years of experience in the Reliability and Condition Monitoring industry. This includes consulting, instrumentation & software design along with implementation of programs around the world in a variety of industries. He has held previous positions that include CEO of Petasense, Inc., Global Director of SKF AB Reliability Systems, and he started his career with IRD Mechanalysis, Inc.

Thanks for subscribing - stay tuned for our next newsletter

Thanks for subscribing - stay tuned for our next newsletter